Lunet

Prosthetic Fingers

2022

Disciplines:

Industrial Design, Healthcare, Mechanical Engineering, 3D Visualization

Industrial Design, Healthcare, Mechanical Engineering, 3D Visualization

Team:

David Edquilang - design, engineering, video production, animation, renders

David Edquilang - design, engineering, video production, animation, renders

Jeff Feng - advisor, clinical liaison

Issue: Nearly 1,000,000 people have fingers amputated every year. Few finger prosthesis options exist and are extremely expensive ($3,000+ per finger).

Design: A fully 3D printable, modular, open source finger prosthesis to meet the need of finger amputees worldwide. Requires zero metal fasteners, no adhesives, nor any special tools to assemble.

The Significance

Worldwide, nearly 1 million people have fingers amputated every year due to injury, infections, and disease.

The incidence is more prevalent in poorer parts of the world with unregulated working conditions.

Few Options Exist

Only two small companies manufacture mechanical finger prostheses.

They charge $3,000+ per finger (often not covered by insurance), which is unaffordable for most people.

Inspired by Performance

Many amputees dislike prostheses that try to resemble a realistic appendage.

Instead, they favor prostheses that simply look cool or techy, since that conveys a sense of performance and high functionality.

Functionality First

Ideation for Lunet consisted of sketching iterations of mechanisms to create a novel finger mechanism.

Once functionality was perfected, the finger was sculpted and refined into its characteristic futuristic appearance for Lunet.

Process

Countless prototypes and sketch iterations of finger mechanisms were created in order to arrive at an optimized design that mimics the range of motion of real fingers, fits the user, and balances functionality, strength, ease of assembly, and aesthetics.

Every mechanism sketch was modeled and prototyped to evaluate and optimize range of motion.

User Testing

Multiple rounds of testing of earlier prototypes with an amputee patient and occupational therapists refined and validated functionality of the design.

Fully 3D Printable

Lunet is 100% 3D printable on any 3D printer, using commonly available PLA and TPE.

This makes it cheap and quick to produce.

This makes it cheap and quick to produce.

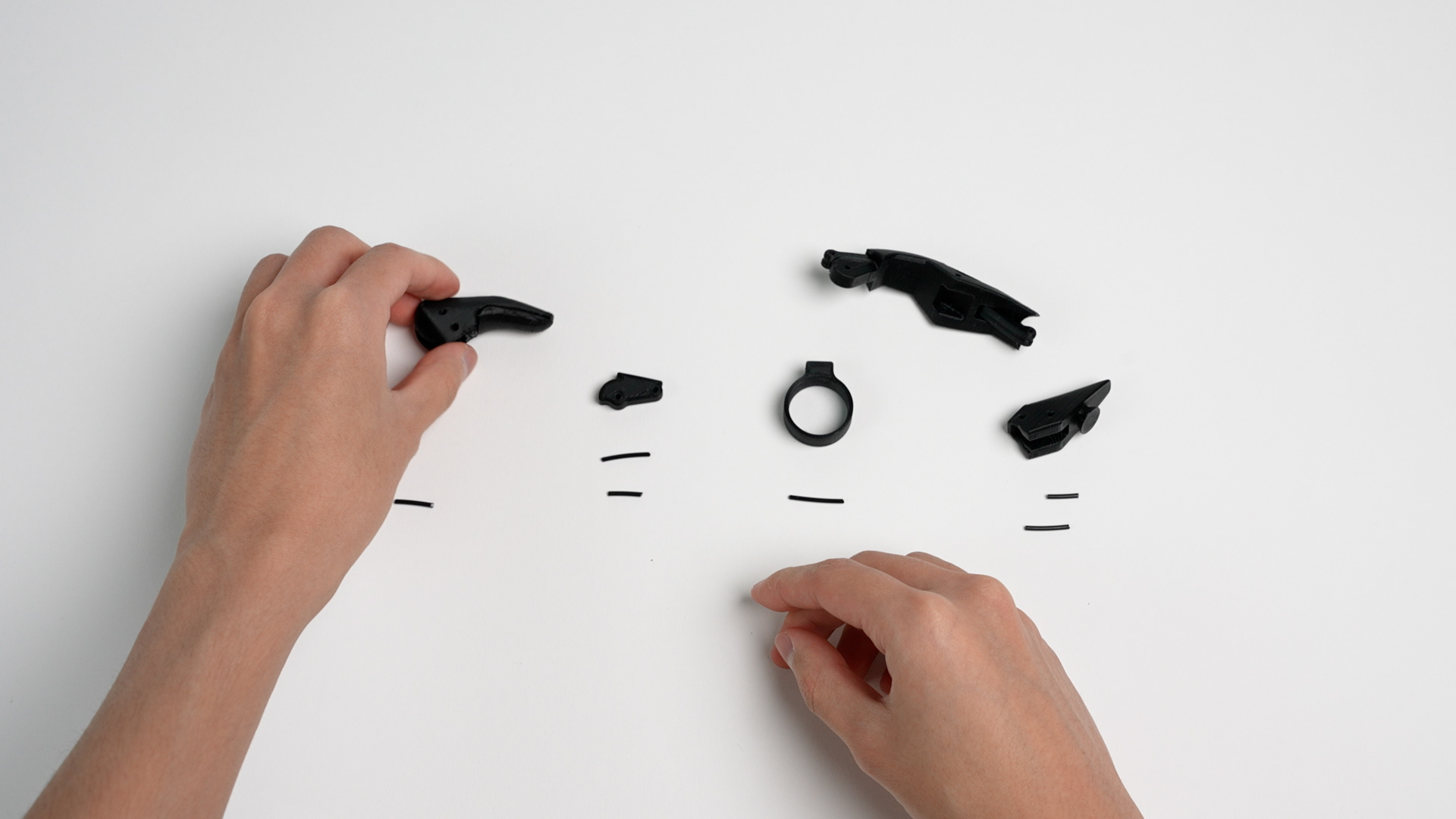

Ease of Assembly

No screws, no glue, no special tools.

Lunet can be assembled in minutes with just your hands, thanks to its snap-together design.

Lunet can be assembled in minutes with just your hands, thanks to its snap-together design.

Natural Motion

Lunet's mechanism is actuated by the user's finger movements, so it moves in tandem with the body - just as expected.

Lunet moves as you move, and is just as strong as you are.

Lunet moves as you move, and is just as strong as you are.

Configurability

With its modular, snap-together design, Lunet can be easily configured to match varying users' anatomical dimensions.

Being 3D printed means it can be infinitely customized in terms of CMF.

Being 3D printed means it can be infinitely customized in terms of CMF.

"Hope lies in dreams, in imagination, and in the courage of those who dare to make dreams into reality."

- Jonas Salk